CAD Designer's

Quick Reference

Fast lookup tool for component selection in mechanical design projects

Find Components Quickly

Search across all component categories to find exactly what you need for your project

Component Categories

Comprehensive reference for the most commonly used mechanical components in CAD design projects

Electric Motors

DC, AC, stepper, servo, and linear motors for all applications

Key Specifications

Applications

Actuators

Electric, pneumatic, and hydraulic actuators for motion control

Key Specifications

Applications

O-Rings & Seals

Sealing solutions by material and form factor

Key Specifications

Applications

Bearings

Ball, roller, thrust, and linear bearings for all load conditions

Key Specifications

Applications

Gears

Spur, helical, bevel, worm, planetary, and harmonic gears

Key Specifications

Applications

Springs & Dampers

Helical, flat, disc springs and shock absorbers for energy storage and damping

Key Specifications

Applications

Hardware & Fasteners

Comprehensive nuts, bolts, screws, and mechanical fastening systems

Key Specifications

Applications

Quick Selection Guide

Fast reference cards for component selection with key specifications, pros/cons, and when to use each type

Motors Quick Reference

DC Brushed Motor

Simple speed control needed

Key Specs

Advantages

Disadvantages

Applications

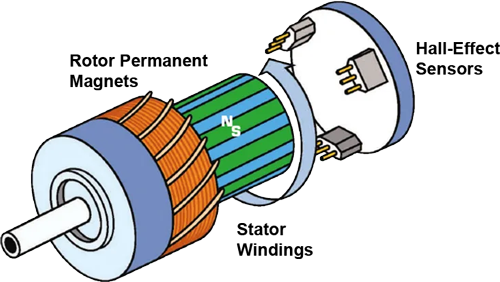

DC Brushless (BLDC)

High efficiency and long life needed

Key Specs

Advantages

Disadvantages

Applications

DC Coreless

Ultra-fast response required

Key Specs

Advantages

Disadvantages

Applications

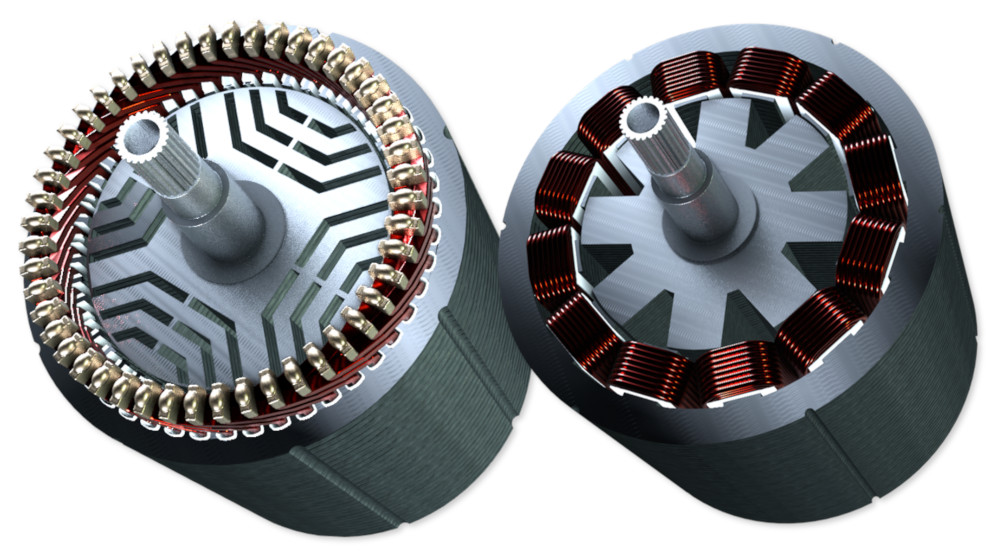

AC Induction (Squirrel Cage)

Robust industrial applications

Key Specs

Advantages

Disadvantages

Applications

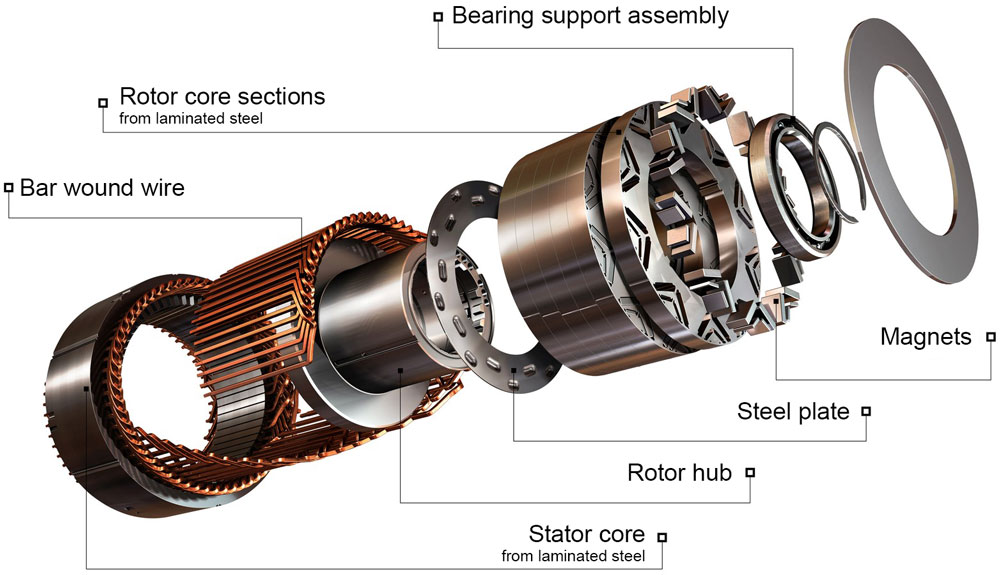

AC Synchronous (PMSM)

High efficiency and precise speed

Key Specs

Advantages

Disadvantages

Applications

Universal Motor

AC/DC operation needed

Key Specs

Advantages

Disadvantages

Applications

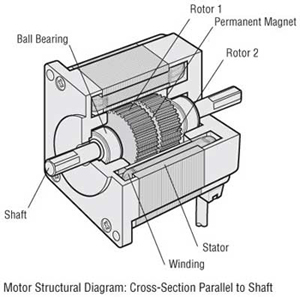

Stepper Motor

Open-loop positioning acceptable

Key Specs

Advantages

Disadvantages

Applications

Switched Reluctance (SRM)

Harsh environments, fault tolerance

Key Specs

Advantages

Disadvantages

Applications

Linear Motor

Direct linear motion needed

Key Specs

Advantages

Disadvantages

Applications

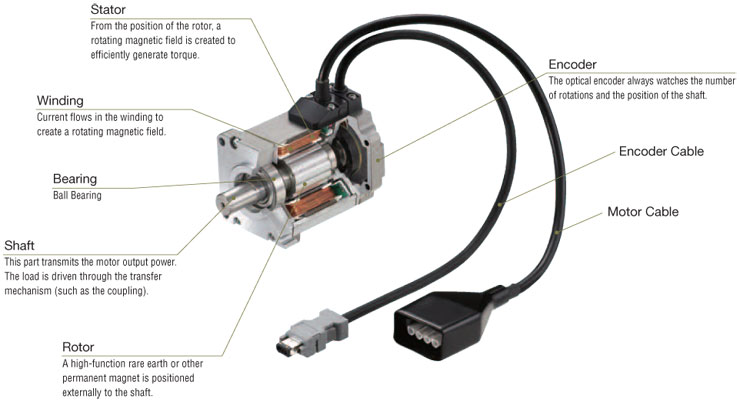

Servo Motor

High precision positioning required

Key Specs

Advantages

Disadvantages

Applications

Ultrasonic Motor

Silent, precise positioning

Key Specs

Advantages

Disadvantages

Applications

Component Comparison Tables

Side-by-side comparison of key specifications, performance characteristics, and selection criteria

Motor Comparison

Compare key characteristics to select the best option for your application

| Type | Efficiency | Speed Control | Cost | Maintenance | Best For |

|---|---|---|---|---|---|

| DC Brushed | 75-80% | Simple | Low | High | Simple applications |

| DC Brushless | 85-90% | Complex | Medium | Low | High efficiency |

| AC Induction | 80-95% | Complex | Medium | Very Low | Industrial drives |

| Servo | 85-90% | Precise | High | Low | Precision control |

| Stepper | 70-85% | Digital | Medium | Very Low | Positioning |

Cost Considerations

Initial cost vs. operational cost over lifetime

Maintenance Requirements

Scheduled maintenance and service intervals

Environmental Factors

Operating conditions and environmental resistance

Manufacturing Processes Reference

Comprehensive guide to manufacturing processes with specifications, applications, and selection criteria

Surface Finishing

Detailed specifications and selection criteria for each manufacturing process

Anodizing

Electrochemical process for aluminum surface treatment

Compatible Materials

Key Specifications

Applications

Advantages

Considerations

Cost Factors

Powder Coating

Dry powder applied electrostatically and cured with heat

Compatible Materials

Key Specifications

Applications

Advantages

Considerations

Cost Factors

Lead Times

Process-dependent timing considerations

Cost Optimization

Volume and design considerations

Material Properties

Process-material compatibility

Quality Control

Inspection and testing requirements

Hardware & Fasteners Reference

Comprehensive catalog of nuts, bolts, and mechanical fastening systems for all applications

Nuts & Threading

Detailed specifications and selection criteria for each fastener type

General-Purpose Nuts

Standard nuts for general applications and structural use

Compatible Materials

Key Specifications

Applications

Advantages

Considerations

Cost Factors

Hand-Tightened Nuts

Nuts designed for hand assembly without tools

Compatible Materials

Key Specifications

Applications

Advantages

Considerations

Cost Factors

Locking Nuts (Vibration-Resistant)

Self-locking nuts that resist loosening from vibration

Compatible Materials

Key Specifications

Applications

Advantages

Considerations

Cost Factors

Flange & Integrated-Washer Nuts

Nuts with built-in washers or flanges for load distribution

Compatible Materials

Key Specifications

Applications

Advantages

Considerations

Cost Factors

Shaft, Bearing & Precision Nuts

Precision nuts for shafts, bearings, and tight-tolerance applications

Compatible Materials

Key Specifications

Applications

Advantages

Considerations

Cost Factors

Sheet-Metal, Captive & Blind Nuts

Nuts for thin materials and blind-side installation

Compatible Materials

Key Specifications

Applications

Advantages

Considerations

Cost Factors

Springs & Dampers Reference

Comprehensive guide to springs and shock absorbers for energy storage, force generation, and motion control

Springs

Detailed specifications and selection criteria for each component type

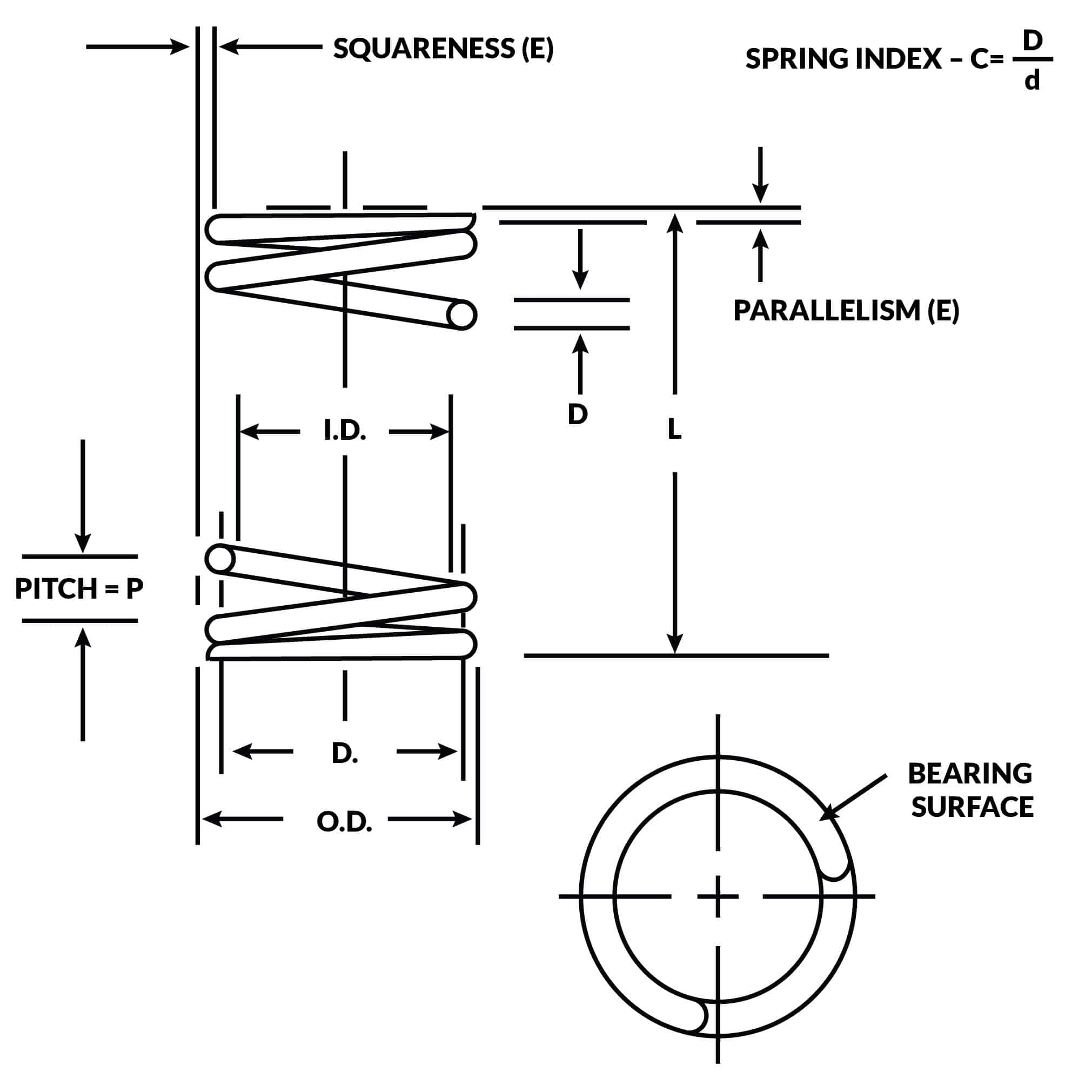

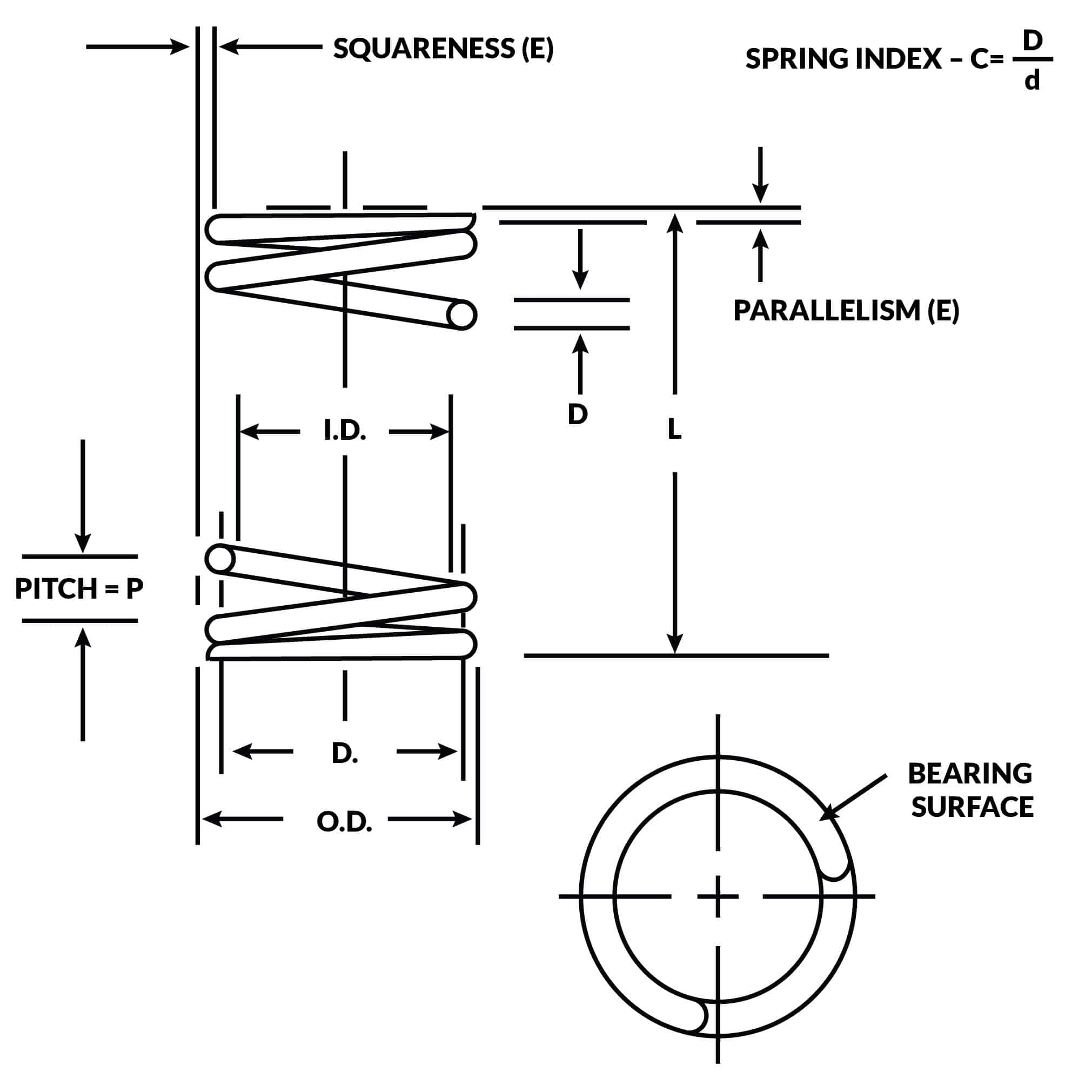

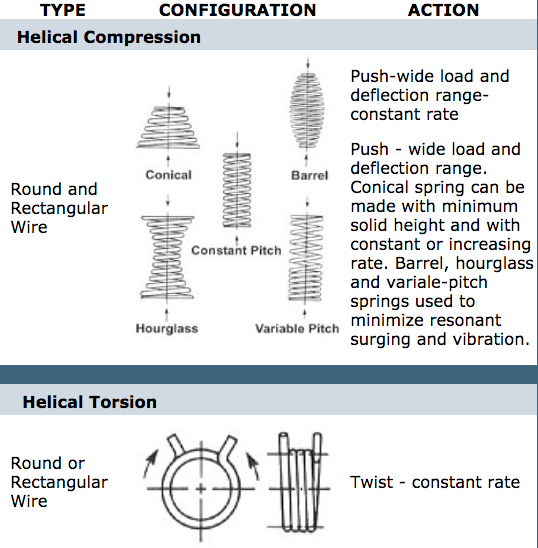

Helical Compression Springs

Round-wire coil springs that resist compression forces

Compatible Materials

Key Specifications

Applications

Advantages

Considerations

Cost Factors

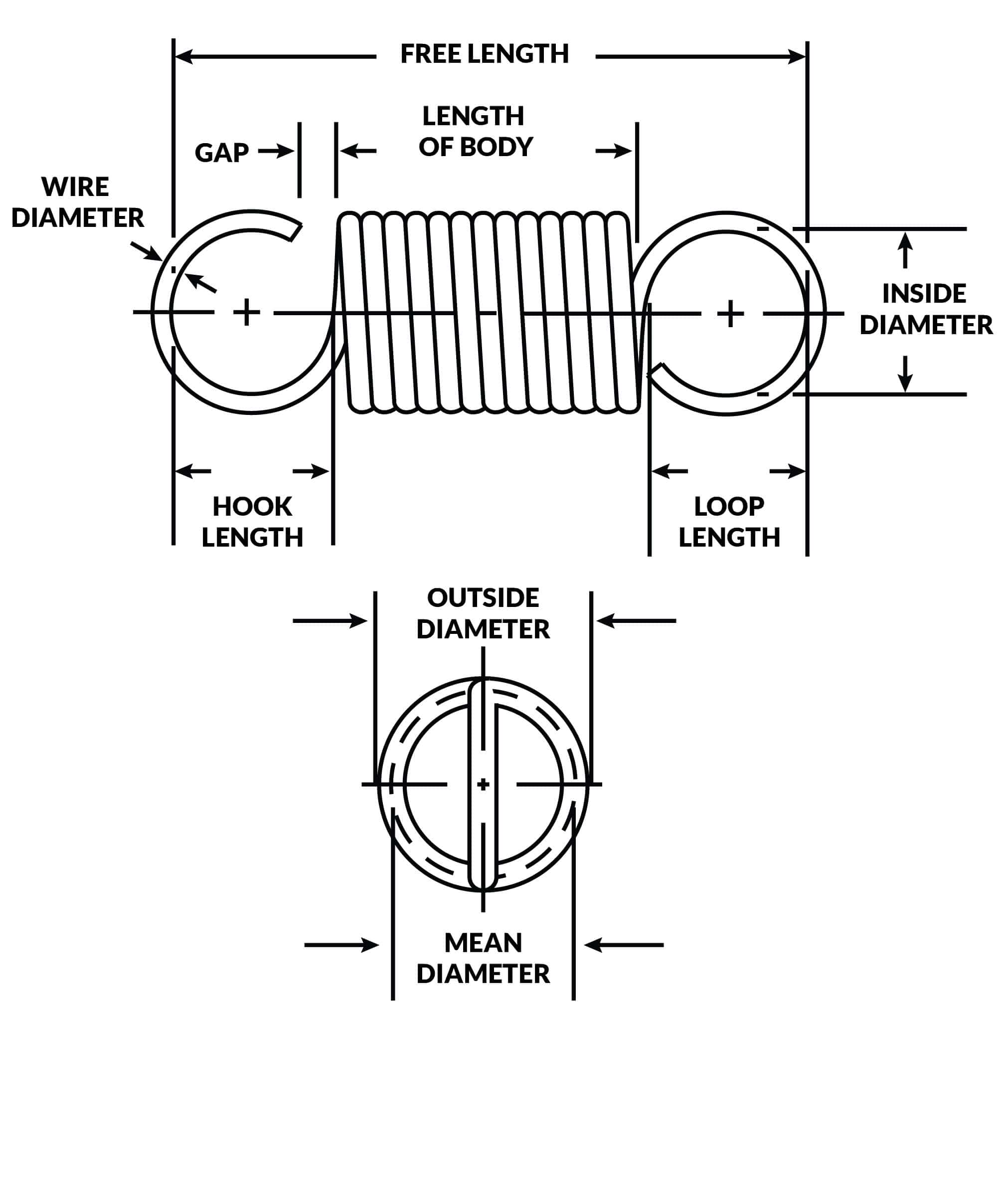

Helical Extension & Torsion Springs

Springs that resist tension forces or provide torque

Compatible Materials

Key Specifications

Applications

Advantages

Considerations

Cost Factors

Flat, Leaf & Spiral Springs

Flat strip springs for specialized applications

Compatible Materials

Key Specifications

Applications

Advantages

Considerations

Cost Factors

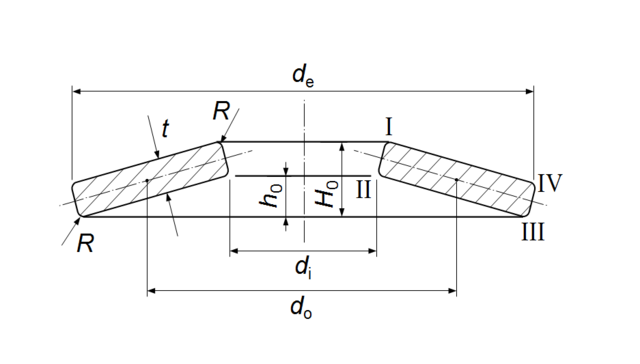

Disc & Washer Springs

Conical disc springs and wave washers for compact applications

Compatible Materials

Key Specifications

Applications

Advantages

Considerations

Cost Factors

Elastomeric & Air Springs

Rubber and air-based spring systems

Compatible Materials

Key Specifications

Applications

Advantages

Considerations

Cost Factors

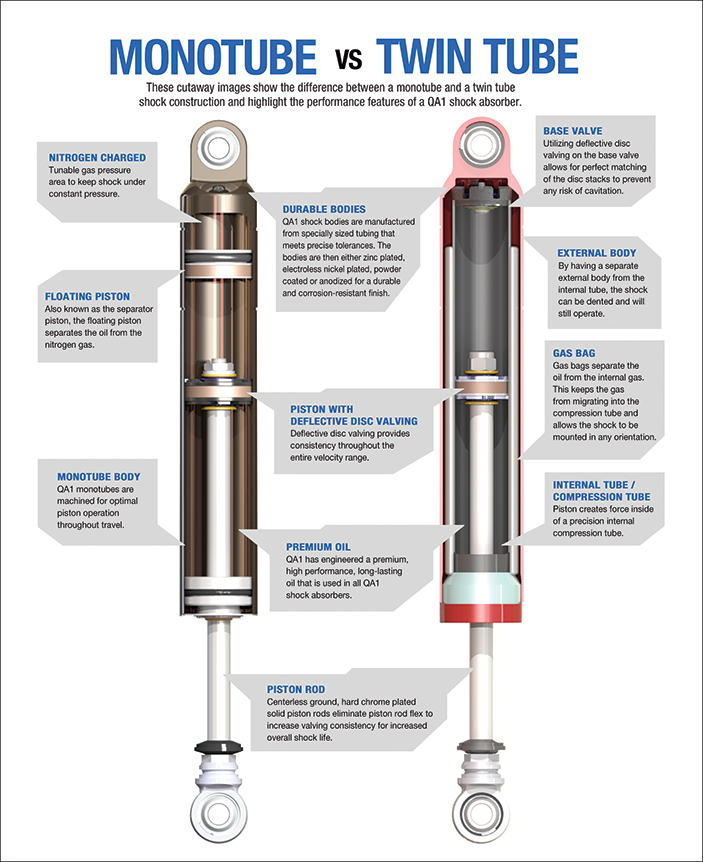

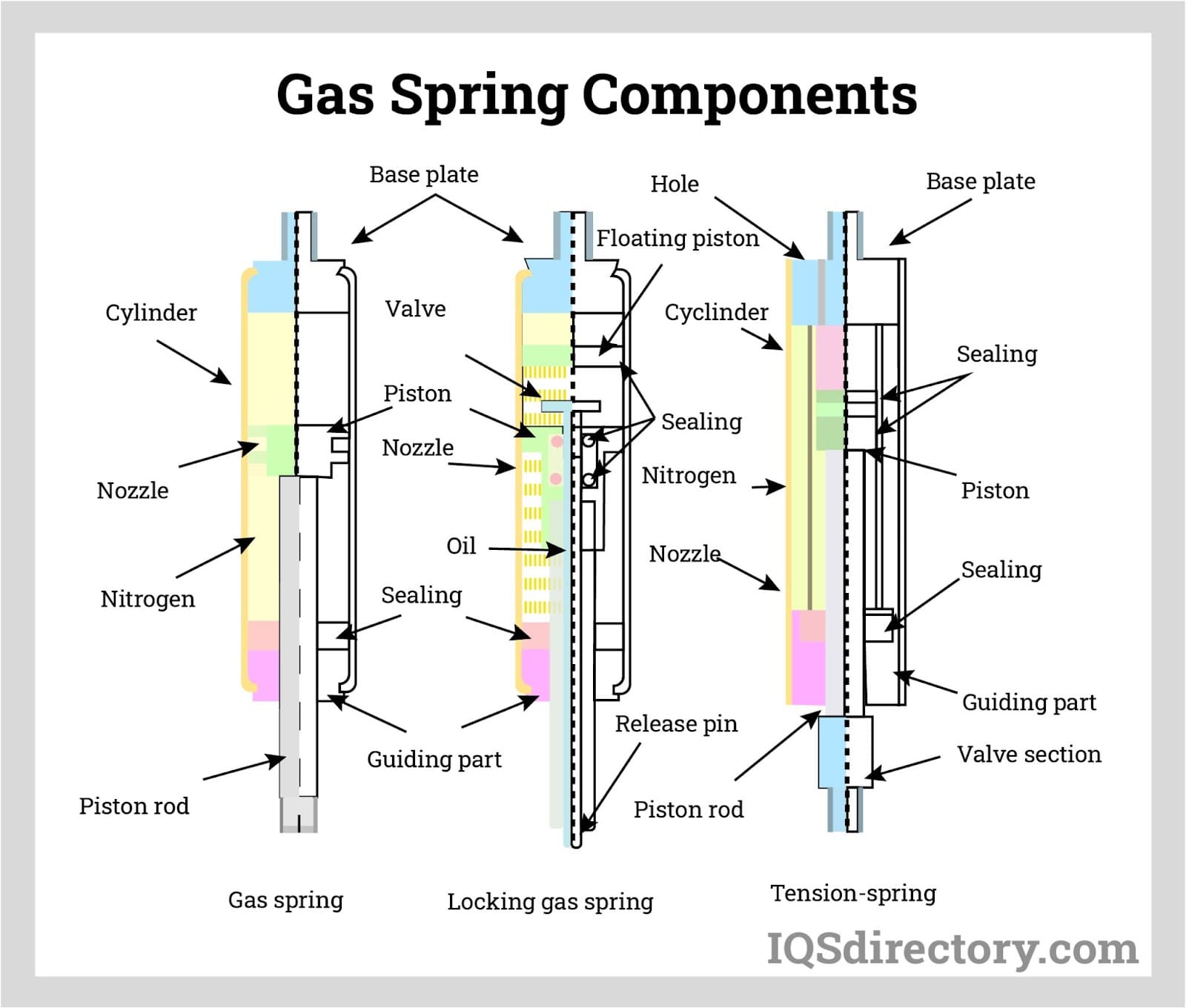

Gas & Hydraulic Springs

Pressurized gas and fluid-based spring systems

Compatible Materials

Key Specifications

Applications

Advantages

Considerations

Cost Factors

Specialty Springs & Retainers

Torsion bars and spring-action fasteners